Products

Complete with classification by

Contact

Tel: 0510-88275668

Fax: 0510-88275118

Contact: Gu Zhuyun, Xu Hong

Sales Phone: 0510-88277755

Sales Phone: 0510-88271100

Sales Fax: 0510-88271558

Address: 8 Chunyang (E), Fangqian, New district, Wuxi, Jiangsu, People`s Republic of China

P.C: 214111

E-mail: wxjianyi@wxjy.com

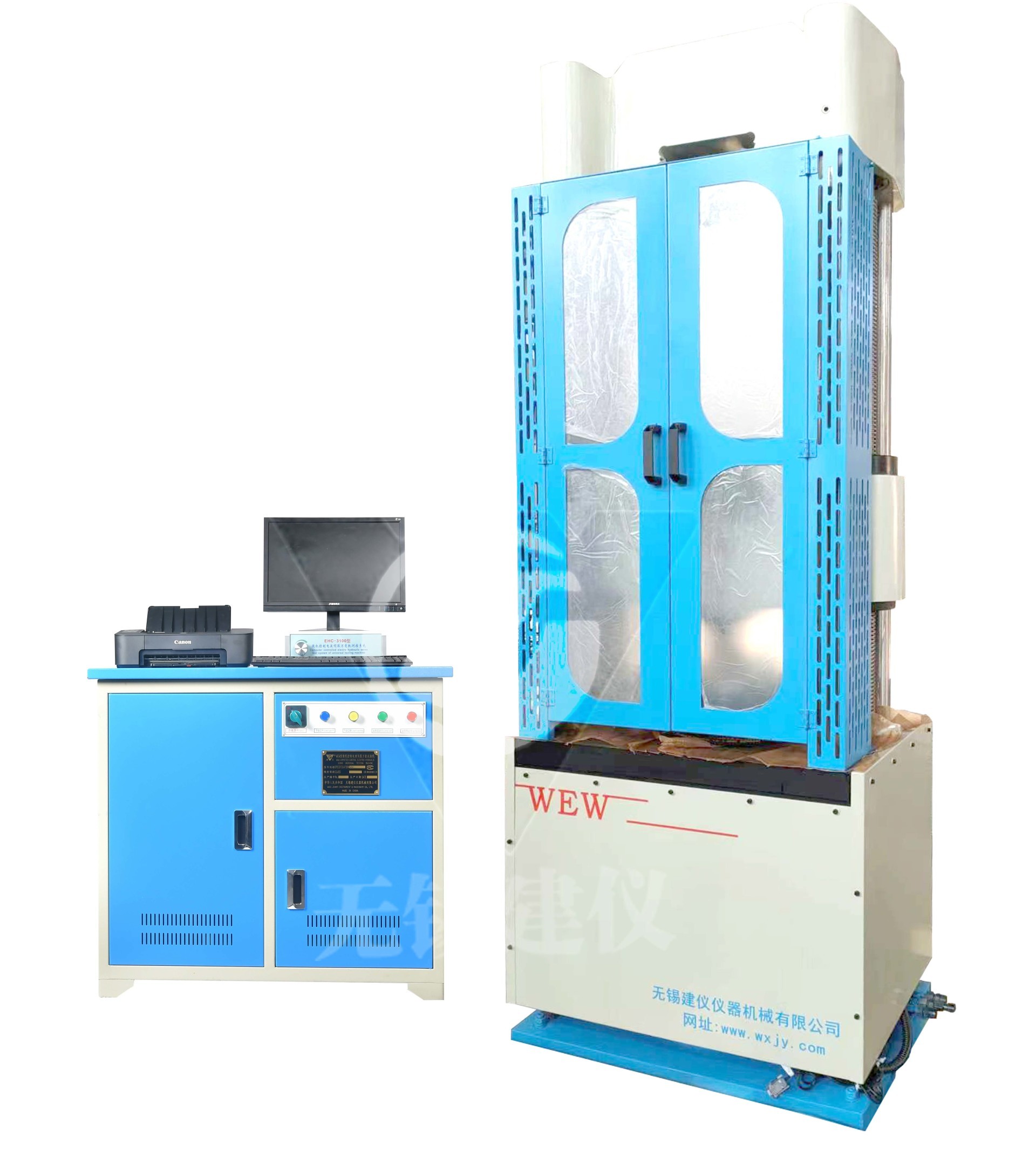

WEW-50D/100D/300D/600D/1000D Microcomputer Control Electro-hydraulic Servo Universal Testing Machine

Price

重量

Inventory

隐藏域元素占位

- Description

-

- Commodity name: WEW-50D/100D/300D/600D/1000D Microcomputer Control Electro-hydraulic Servo Universal Testing Machine

W E W 's D series microcomputer-controlled electro-hydraulic servo universal testing machine is mainly used for tensile, compression, shear and bending tests of metal materials. Equipped with suitable fixtures, it can also be used for compression tests of non-metallic materials such as concrete, brick and stone. Comply with national standard GB/T2611-2007 , GB/T16826-2008 . Meet the national standard GB/T 228.1 -20 10 , GB/T2 32 -20 10 . Features: Microcomputer control, servo pump control, energy saving and environmental protection.

WEW's D series microcomputer-controlled electro-hydraulic servo universal testing machine is mainly used for tensile, compression, shear and bending tests of metal materials. Equipped with suitable fixtures, it can also be used for compression tests of non-metallic materials such as concrete, brick and stone. Comply with national standard GB/T2611-2007 , GB/T16826-2008 . Meet the national standard GB/T 228.1 -20 10 , GB/T2 32 -20 10 . Features: Microcomputer control, servo pump control, energy saving and environmental protection.

model

the project

WEW-50D(100D)

WEW-300D

WEW-600D

WEW-1000D

Maximum test force ( kN)

50 (100)

300

600

1000

Measuring range ( kN)

1-50 (2-100)

6-300

12-600

20-1000

Accuracy class

Level 1/0.5

Accuracy of test force indication ( %)

±1/±0.5

Deformation measurement range (㎜)

1%~100%F·S

Deformation indication accuracy ( %)

±1/±0.5

Accuracy of displacement indication ( %)

±1/±0.5

Maximum distance of stretching jaws (including piston stroke) (㎜)

450

600

700

650

Maximum distance between upper and lower pressure plates (including piston stroke) (㎜)

540

700

580

580

Distance between columns (㎜)

400

460

520

520

Piston stroke (㎜)

150

250

Round sample clamping diameter (㎜)

φ6

φ10

Φ

φ20

Flat sample clamping thickness

0

0~25/70

0~30/95

0~40/95

Upper pressure plate size (㎜)

F

205×205

Lower pressure plate size (㎜)

F

F

Maximum distance between bending rollers (㎜)

215

300

Number of columns (roots)

2

4

Number of screw rods (roots)

2

Piston rising speed (

≥300

≥200

≥100

≥80

power supply

380V 50Hz 2.2kW

Host Dimensions (

650×500×1894

820×550×

1000×650×2150

1000×700×2200

Force measuring system size (

610

Host weight (

1400

1850

2000

2500

Weight of force measuring system ( kg )

400

Related products

Related products

Message