FAQ

Contact

Tel: 0510-88275668

Fax: 0510-88275118

Contact: Gu Zhuyun, Xu Hong

Sales Phone: 0510-88277755

Sales Phone: 0510-88271100

Sales Fax: 0510-88271558

Address: 8 Chunyang (E), Fangqian, New district, Wuxi, Jiangsu, People`s Republic of China

P.C: 214111

E-mail: wxjianyi@wxjy.com

Distinguishing and adjusting method of mechanical and physical zero position of proportional valve

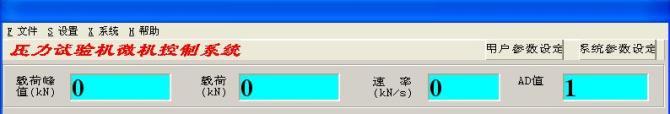

After the normal operation program is loaded, when the test block is just under pressure, pay attention to the load peak column as shown in the figure below:

After the normal operation program is loaded, when the test block is just under pressure, pay attention to the load peak column as shown in the figure below:

Generally, the load peak value should be between 0-3kN when the test block is just under pressure. If it exceeds 3kN, it indicates that the physical zero position of the proportional valve may be ahead.

Judging the failure of the physical zero position of the proportional valve in the program operation

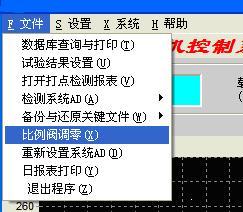

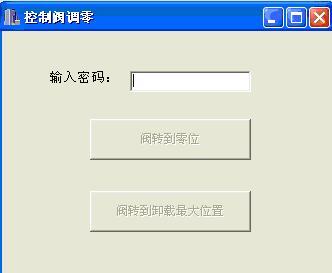

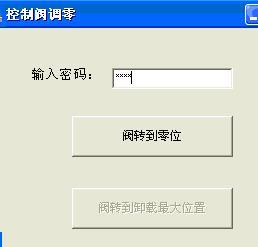

1. Open the computer program, click "File" and select "Proportional Valve Zero Adjustment", enter the password: "wxjy":

2. Turn off the oil pump motor of the pressure machine, turn on the controller, and click the "valve to zero" button.

3. At this time, turn on the oil pump motor of the pressure machine and carefully observe the piston. If the piston is in a state of upward movement, it indicates that the mechanical and physical zero position of the proportional valve is forward.

Solution:

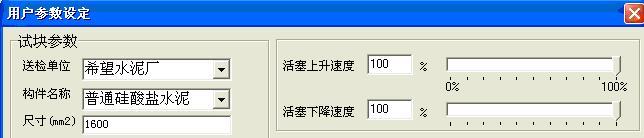

First, try to reduce the percentage of "piston rising speed" in the user parameter setting slightly, and repeat the previous judgment process until the zero adjustment is successful;

If the "piston rising speed" percentage is reduced to 40%, the mechanical physical zero position of the proportional valve is still forward, you need to manually adjust the mechanical physical zero position on the proportional valve, the method is as follows:

1. First adjust the piston rising speed to 80% in the "User Parameter Setting".

2. Open the computer program according to the above method, click "File", select "Proportional Valve Zero Adjustment", enter the password, turn off the pressure machine oil pump motor, open the controller, and click the program "Valve to Zero" button.

3. Open the back door of the press, face the sector gear of the proportional valve, and loosen the locking screw (3mm hex wrench) that fixes the 5×5mm square spool at the bottom of the sector gear.

4. Turn on the oil pump motor of the pressure machine, and adjust the zero position of the 5×5 square spool with a 5.5mm wrench or pliers: turn clockwise to adjust the mechanical and physical zero position of the proportional valve forward, and turn counterclockwise to move the proportional valve The mechanical physical zero position is adjusted. Note: The adjustable range of the mechanical and physical zero position of the proportional valve is very small, and it needs careful and repeated micro-adjustment.

5. When the program shows "valve turns to zero", adjust the zero position of the spool so that the piston is in a slightly lowered state.

6. Turn off the oil pump motor of the pressure machine, and tighten the 3mm inner hexagonal locking screw that fixes the spool.

7. Start the normal test to verify the mechanical and physical zero position of the proportional valve:

A If the piston does not rise or the rising speed is too slow, adjust the mechanical and physical zero position of the proportional valve forward according to the above method.

B If the rising speed of the piston is too fast or the "load peak value" in the program interface initially displays more than 3kN when the test block is just under pressure, then adjust the mechanical and physical zero position of the proportional valve according to the above method.